Skill Builder: 4-Axis Mill

Not sure why but I wasn’t super excited for the 4-axis mill. As a machine, what it does can be magical. However, it just felt unapproachably expensive. It’s not something you’ll find in your standard makerspace. Nor is it something you’d ever buy.

Concept

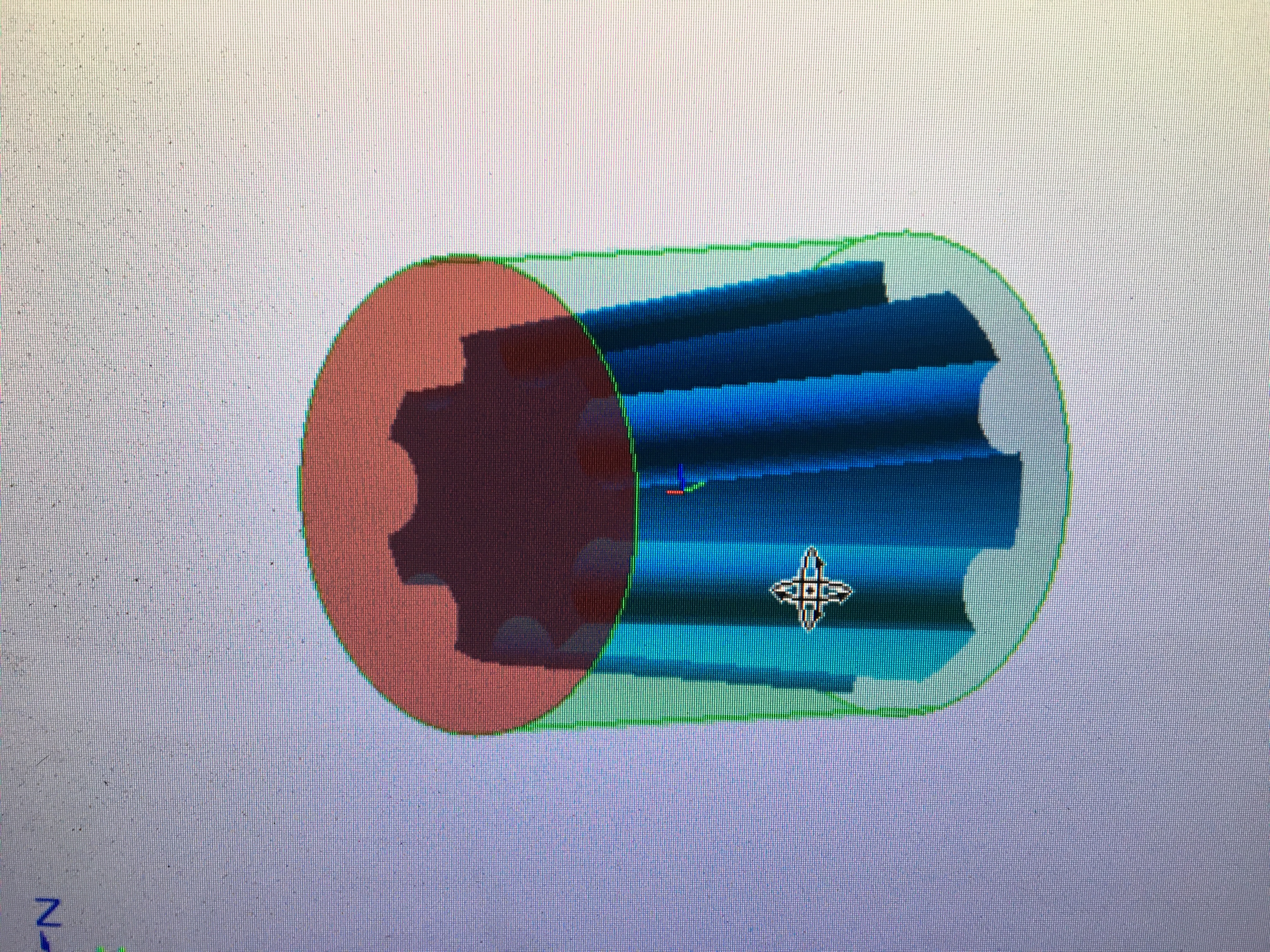

But nevertheless, it can really do some different things that the other tools can’t quite achieve. For one, I figured it would be easy to print out a mini-prototype of the knob design that I wanted to build last semester (before we decided it was too difficult with our knowledge at the time).

The dream knob, with ridges.

The dream knob, with ridges.

Material

Some leftover dowel from lathe projects.

Some leftover dowel from lathe projects.

Setup

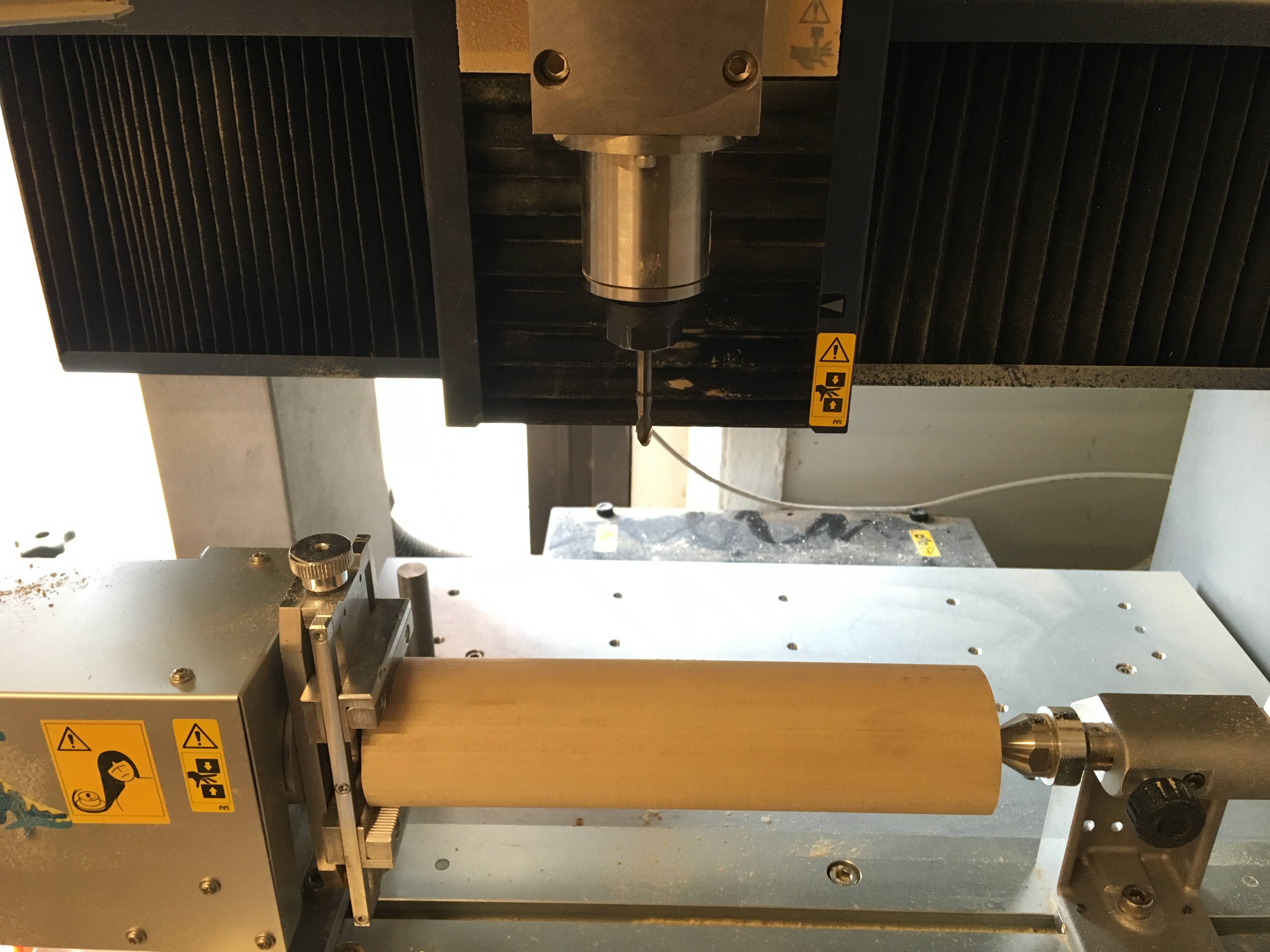

Setting up the blank.

Setting up the blank.

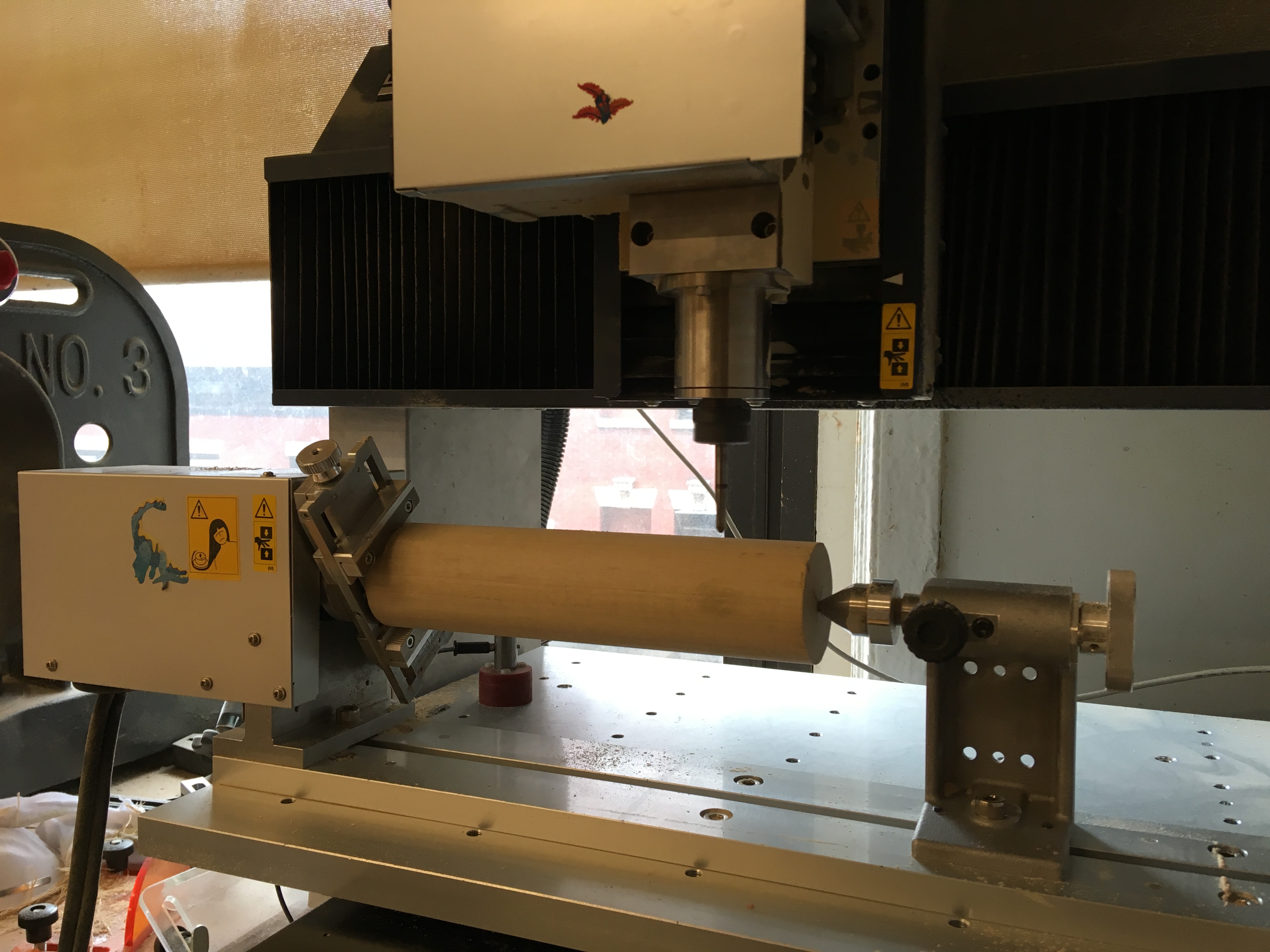

Setting up the axes.

Setting up the axes.

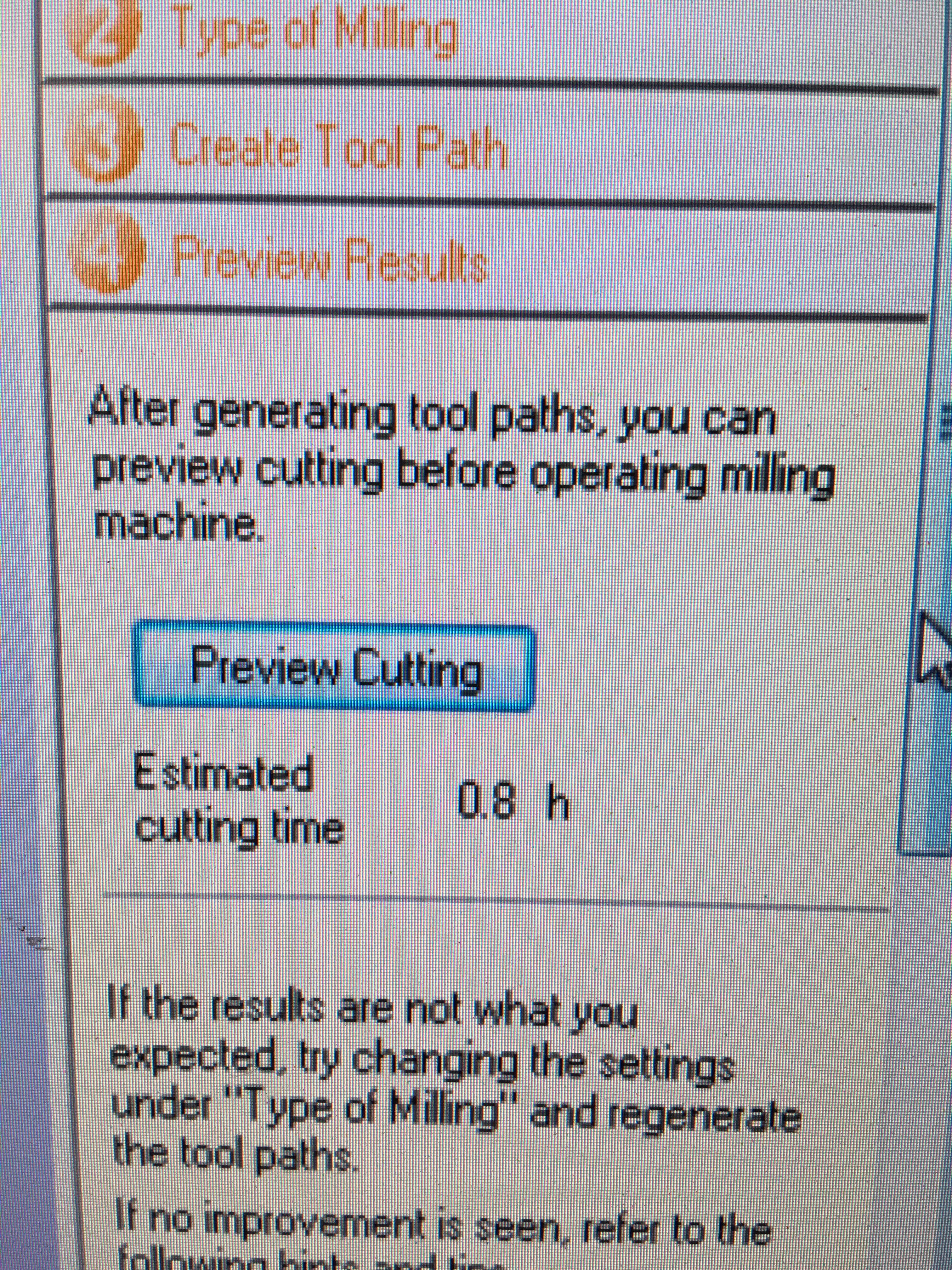

Big estimate. Not as scary as I thought it would be.

Big estimate. Not as scary as I thought it would be.

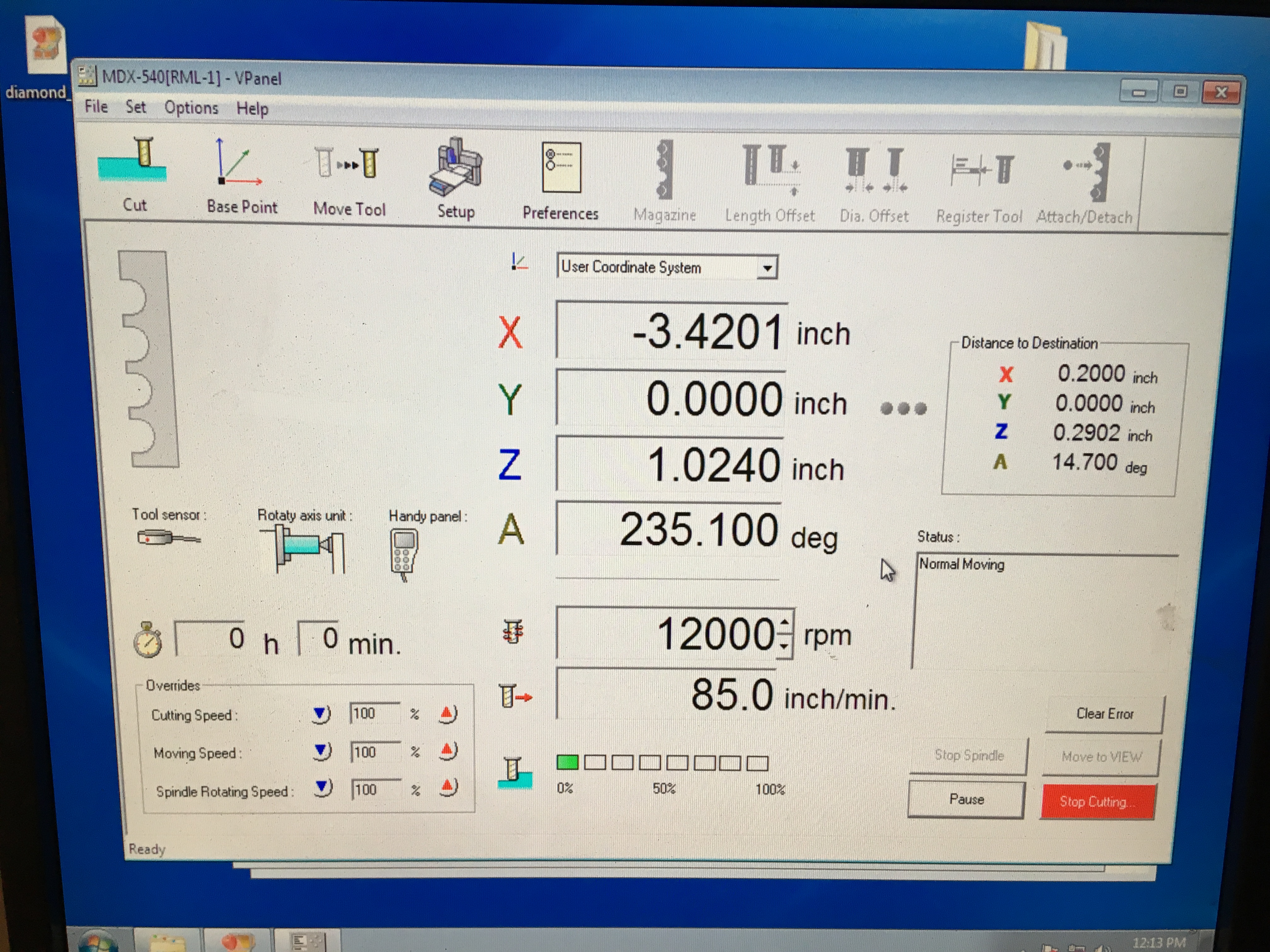

This interface is overwhelming.

This interface is overwhelming.

Processing

Cutting it up.

Cutting it up.

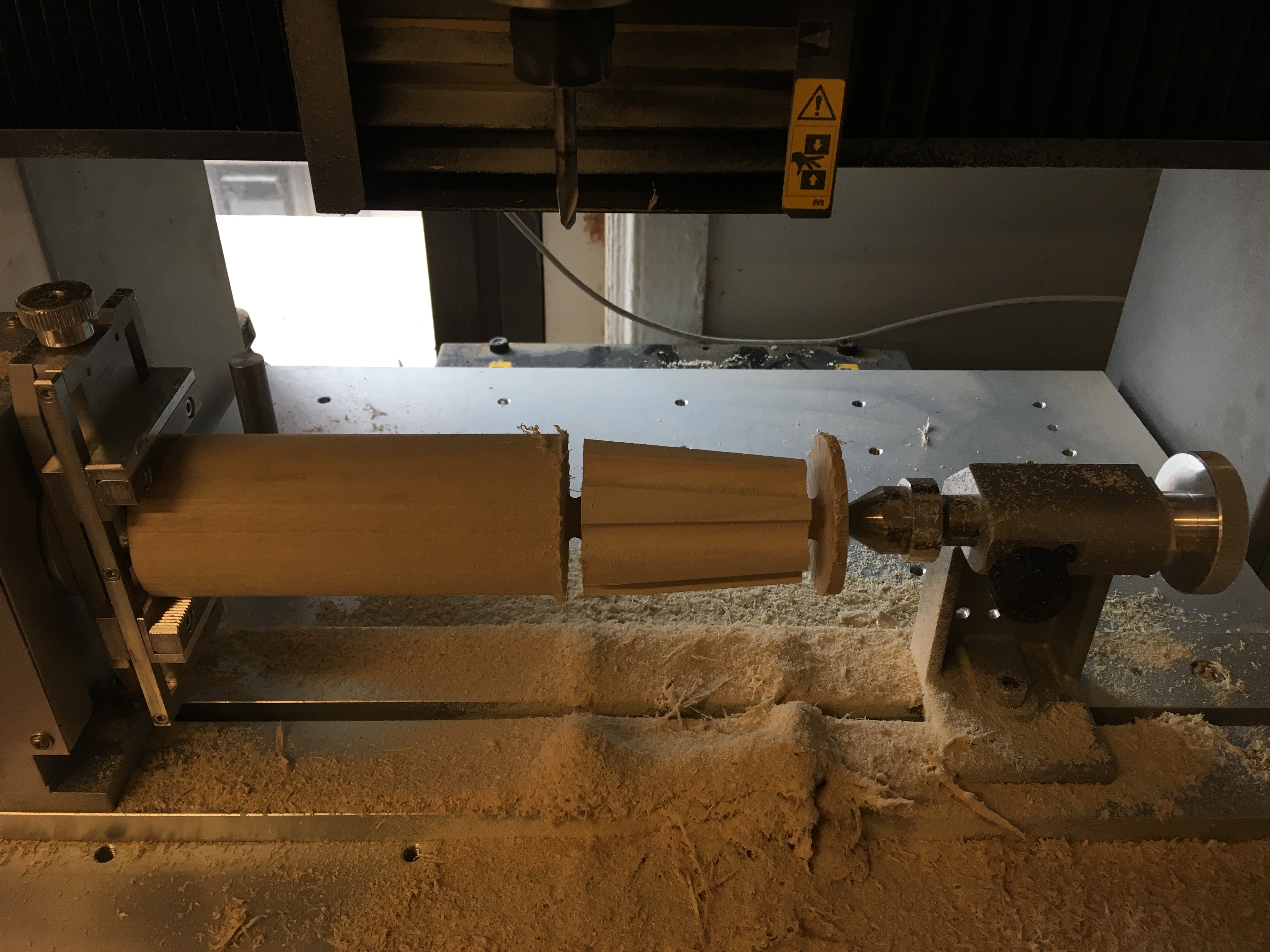

Rough pass. Kind of skeptical it will turn out well.

Rough pass. Kind of skeptical it will turn out well.

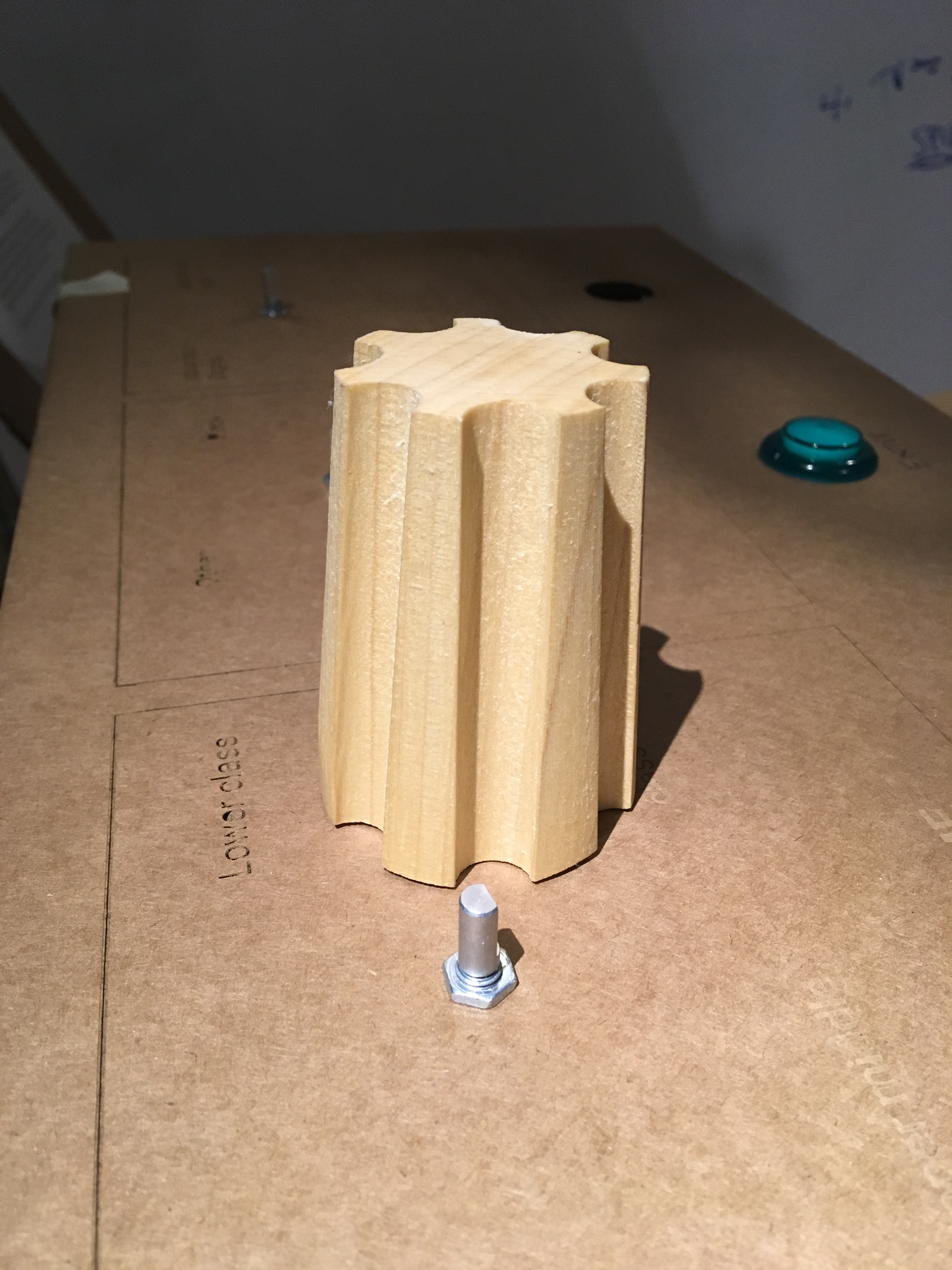

Finishing pass! It looks greater than I thought.

Finishing pass! It looks greater than I thought.

Getting dusty.

Getting dusty.

Final

I added a light coat of tung oil to darken it just a little.

Learnings

This machine seems frustratingly slow.

The way it contours material could be improved with some lathe-like toolpaths. For example, when it cuts tabs on both sides it hits one point on the left, lifts, hits one point on the right, lifts, rotates slightly, and repeats. Whereas it seems like it would be a lot more efficient (for round stock) to rough in a circular motion to reduce bit travel time…

Also this community roundnose drillbit has seen some better days. Definitely get your own if you plan on doing more work with this machine.

If I did this again, I’d print it without tabs… and just bandsaw and sand to finish to really save on time. Your going to sand the two tabbed sides anyway…