HAMMER TIME on ITP's Wood Lathe

Hammer Time!

This week, I built a mallet to gift to my camp, conveniently named HAMMER TIME.

Testing with a Poplar Dowel

This was my first time doing interlocking parts on the lathe, so I wanted to test everything before messing up my precious block of beautiful maple. I had a large poplar dowel sitting around so I figured I’d mill it a bit and practice drilling the two main holes I would need to attach the handle: the hole for the handle and the hole to insert the dowel into the handle.

Scrap poplar dowel

Scrap poplar dowel

Getting a rough cut and practicing some curvature

Getting a rough cut and practicing some curvature

Drawing a centerline

Drawing a centerline

Here’s where things start to get tricky.

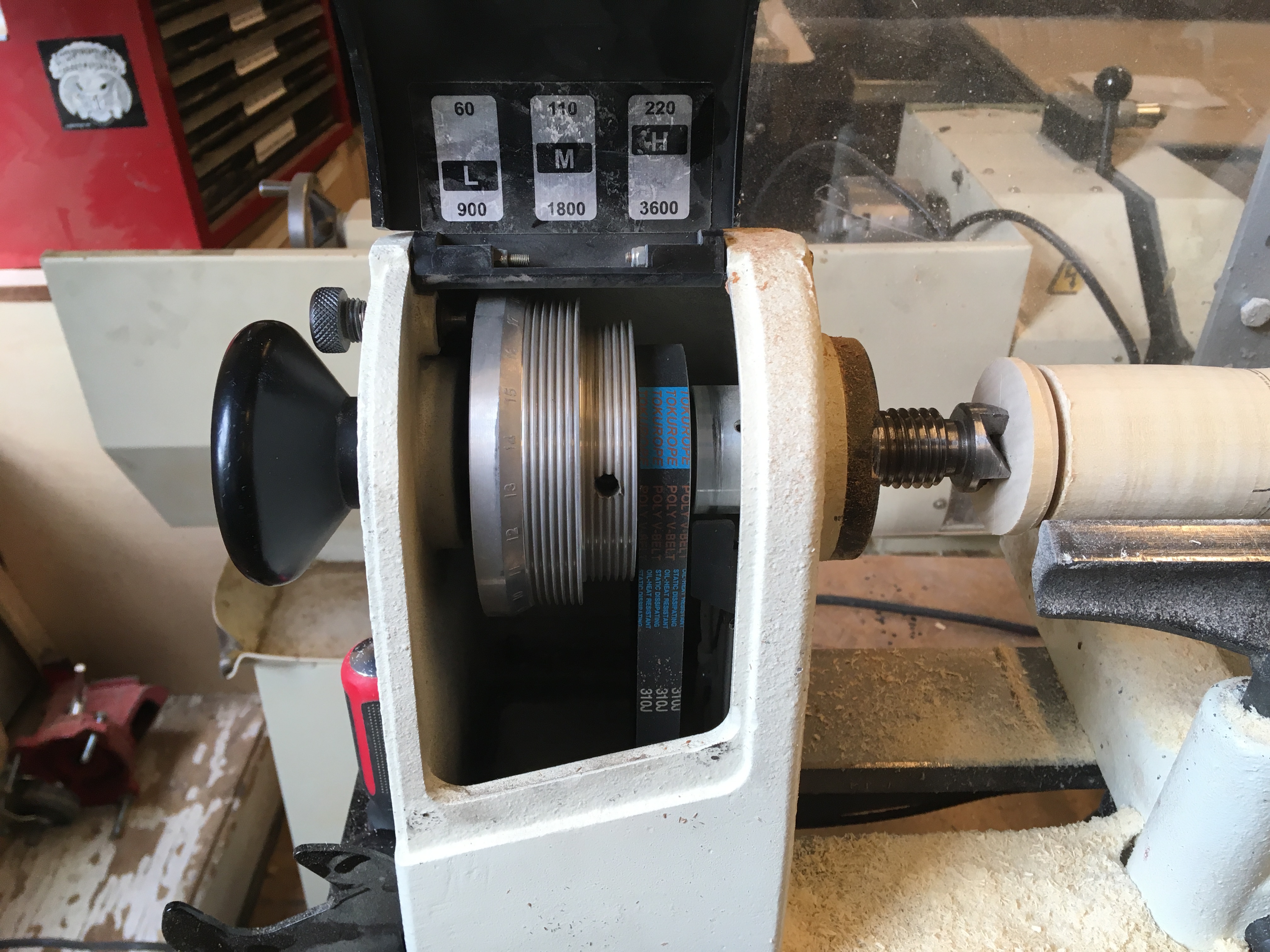

Using the lathe’s manual turning, I measured out an arbitrary center. And then from that marked center I measured out plus and minus 60 degrees. These would be my dowel holes. (I chose 60 degrees instead of 90 degrees because I really want my dowel rod below center.)

Using the lathe’s manual turning, I measured out an arbitrary center. And then from that marked center I measured out plus and minus 60 degrees. These would be my dowel holes. (I chose 60 degrees instead of 90 degrees because I really want my dowel rod below center.)

Drill press a 3/4” hole to fit the rod

Drill press a 3/4” hole to fit the rod

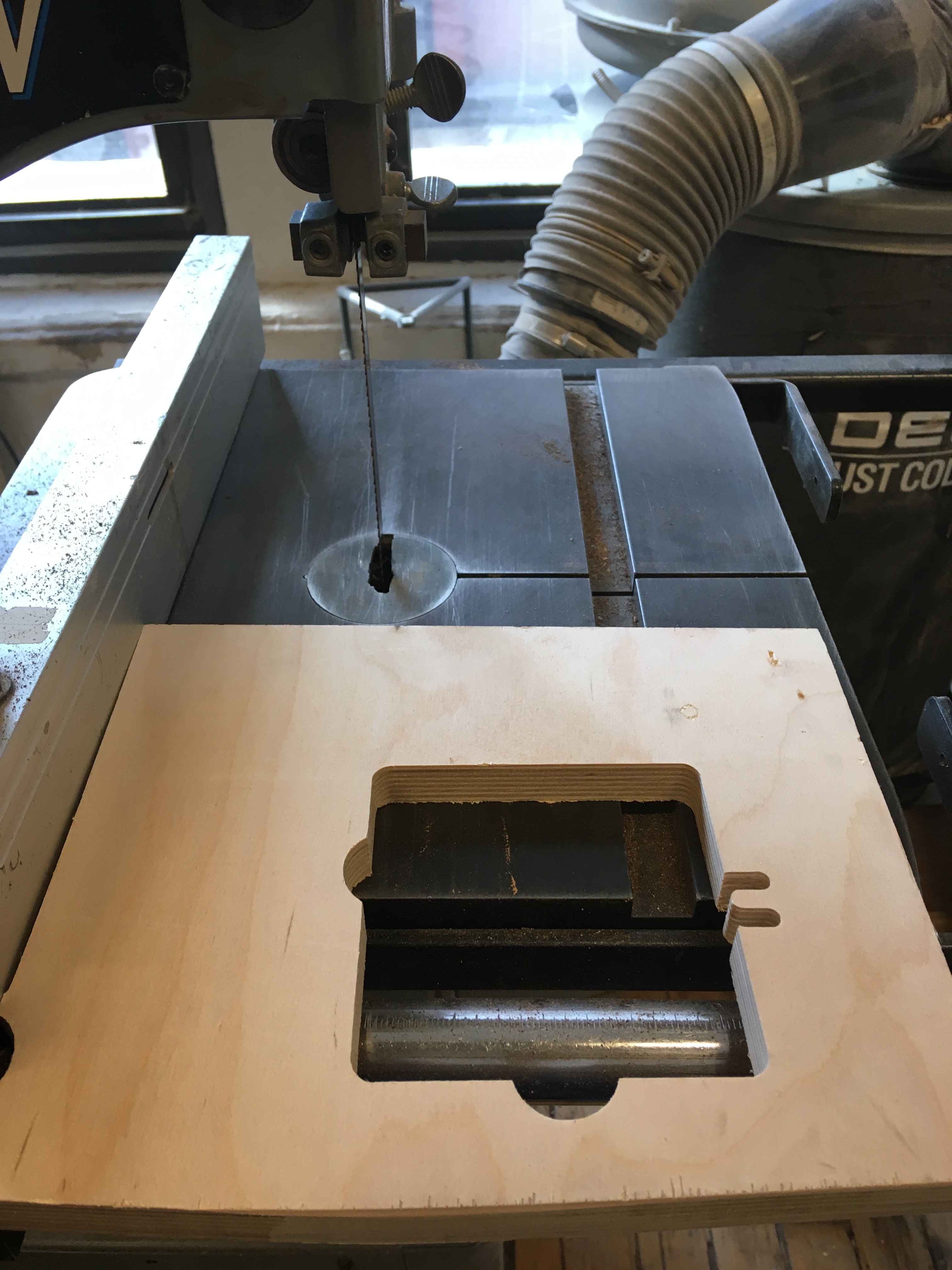

Using some playwood scrap I start to make a jig

Using some playwood scrap I start to make a jig

Lathing plywood in this direction proved incredibly difficult. This was the most time consuming part of the entire project. Eventually, I got it just right!

Lathing plywood in this direction proved incredibly difficult. This was the most time consuming part of the entire project. Eventually, I got it just right!

The jig fits!

The jig fits!

Turning the Maple Mallet Head

Beautiful piece of maple ordered from Woodcraft. Took a while to deliver so I really didn’t want to mess this part up.

Beautiful piece of maple ordered from Woodcraft. Took a while to deliver so I really didn’t want to mess this part up.

Finding the center.

Finding the center.

Roughing it was pretty scary.

Roughing it was pretty scary.

…but I finally got it round and the fun begins

…but I finally got it round and the fun begins

Shaping a gavel-style mallet with a fat center.

Shaping a gavel-style mallet with a fat center.

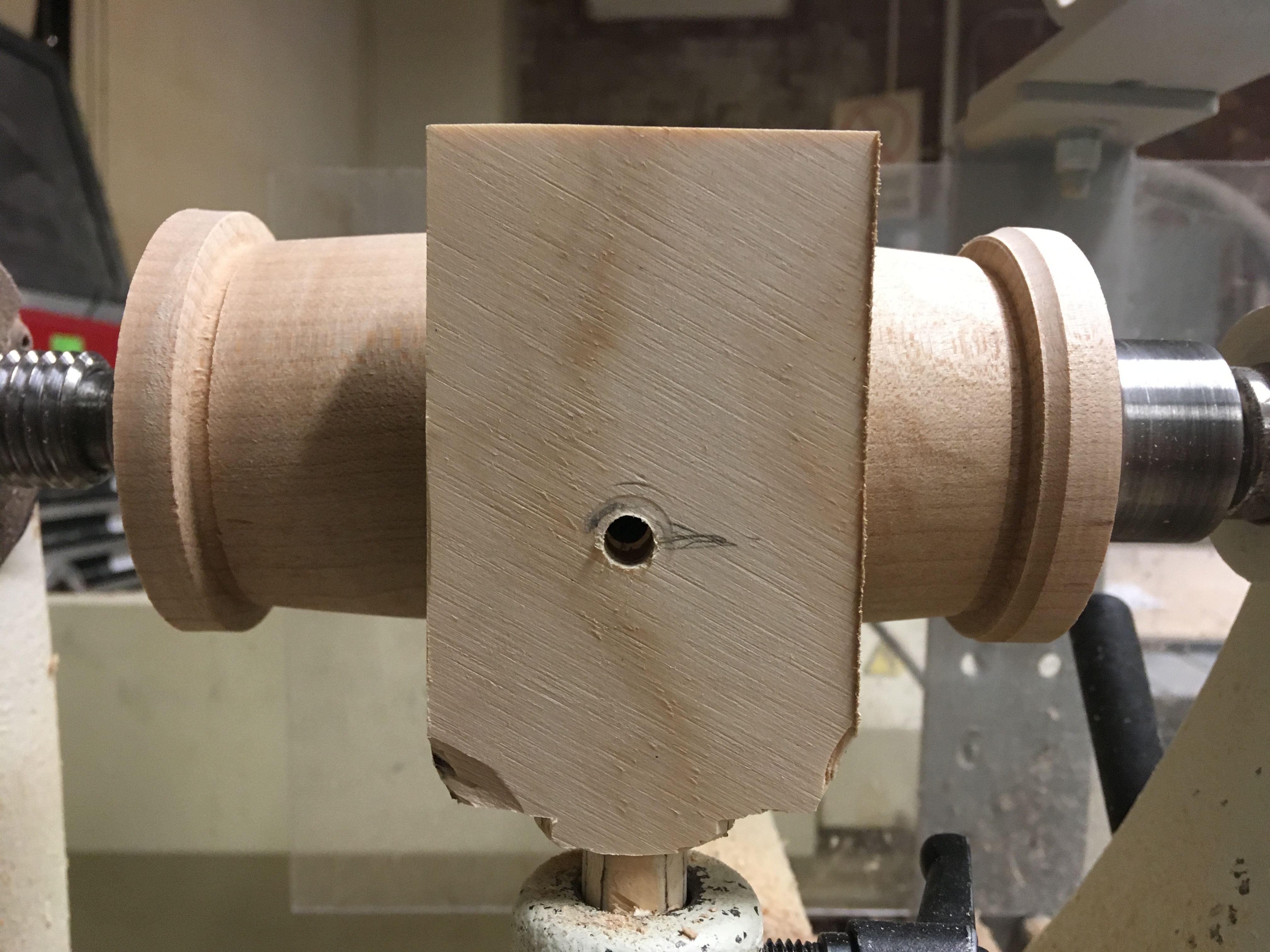

Using the jig I created earlier to drill a hole for the dowel.

Using the jig I created earlier to drill a hole for the dowel.

Unfortunately, my drill bit wasn’t long enough so I only drilled a hole on one side. This was simpler, and I think more aesthetically pleasing this way.

Unfortunately, my drill bit wasn’t long enough so I only drilled a hole on one side. This was simpler, and I think more aesthetically pleasing this way.

Using a V-block, I drill press a hole for the rod to fit.

Using a V-block, I drill press a hole for the rod to fit.

Turning the Oak Mallet Handle

Putting it Together

Finishing Touches

Because I had one clean side without a dowel hole, I decided to etch it.

Because I had one clean side without a dowel hole, I decided to etch it.

HAMMER TIME!

HAMMER TIME!

And lastly, two layers of tung oil to finish it all off

And lastly, two layers of tung oil to finish it all off

HAMMER TIME