Repeatables: Whiskey Ball Wood Prototypes!

I set out to make a geodesic dome with repeatable geodesic dome connectors. Clearly, this isn’t a geodesic dome. Manufacturing the connectors proved too difficult. Instead I chose to explore making a spherical ice ball machine to up my whiskey drinking game. These are wood prototypes and lacking in a few features – e.g. I didn’t get a ball plunge bit in time. But they’re still useful for a possible physical computing project. Anyway, this all proved to be a great start for a production run with aluminum bar that I’m hoping to make next month for awesome Christmas Gifts.

The inspiration. You might be this in the wild for a very overpriced $1000.

The inspiration. You might be this in the wild for a very overpriced $1000.

Pancaking, with an eye towards repeatability.

2x4s from the Grumpy McGrumperson at Metropolitan Lumber. A reminder to learn your materials!

2x4s from the Grumpy McGrumperson at Metropolitan Lumber. A reminder to learn your materials!

Lesson 1: WTF? 2x4s are not actually 2x4in, but instead have nominal and actual dimensions. Useful Jump

What I really wanted was a 4x4 but not sure that exists. Grumpy McGrumperson not helpful. Glued two 2x4s together. Weird clamps for the win. My clamp game is strong.

What I really wanted was a 4x4 but not sure that exists. Grumpy McGrumperson not helpful. Glued two 2x4s together. Weird clamps for the win. My clamp game is strong.

Testing out first try at center-punch and circle-drawing jig. Too big… see 2x4 notes above. =X

Testing out first try at center-punch and circle-drawing jig. Too big… see 2x4 notes above. =X

One measurement. Don’t need to be precise here because I’m just going to stop block everything > 1.

One measurement. Don’t need to be precise here because I’m just going to stop block everything > 1.

Stop Block and Mitre On

Stop Block and Mitre On

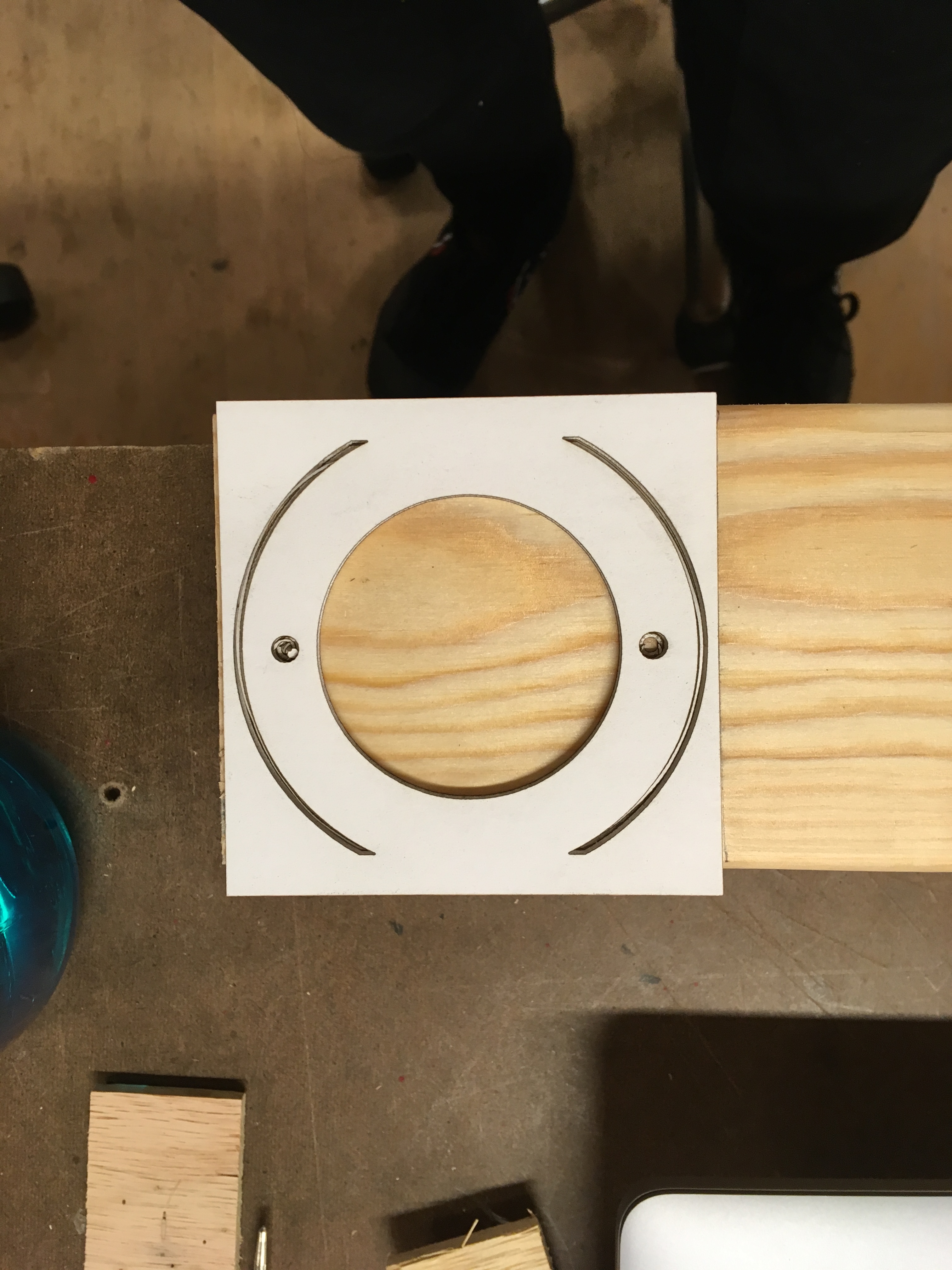

Lasercut center-punch jig with cutouts for tracing circle we’ll need later.

Lasercut center-punch jig with cutouts for tracing circle we’ll need later.

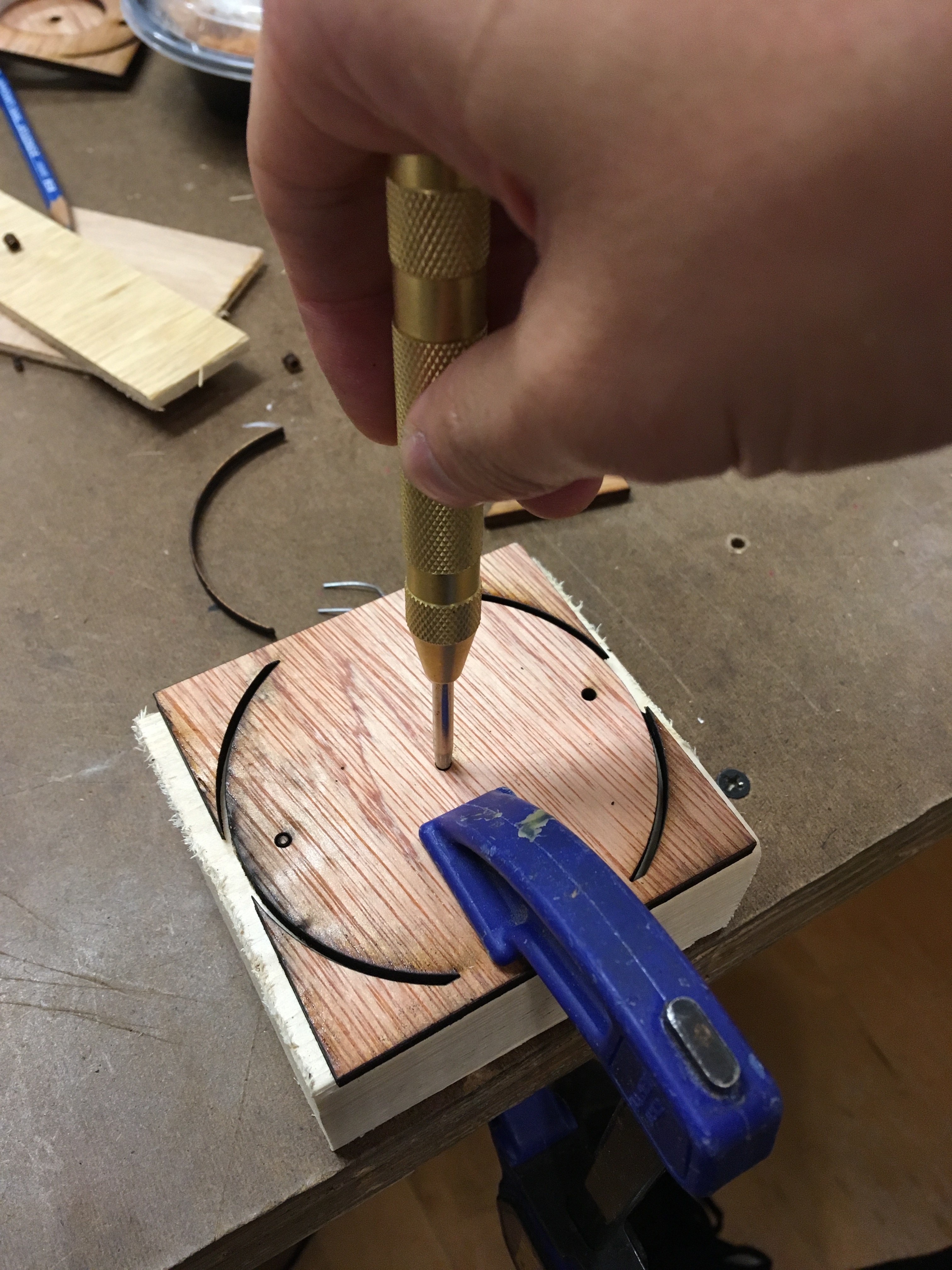

Center-punching feels so damn good.

Center-punching feels so damn good.

Prepping the drill press. Two clamps make a HUGE difference in preventing slippage. Use >= 2 clamps!

Prepping the drill press. Two clamps make a HUGE difference in preventing slippage. Use >= 2 clamps!

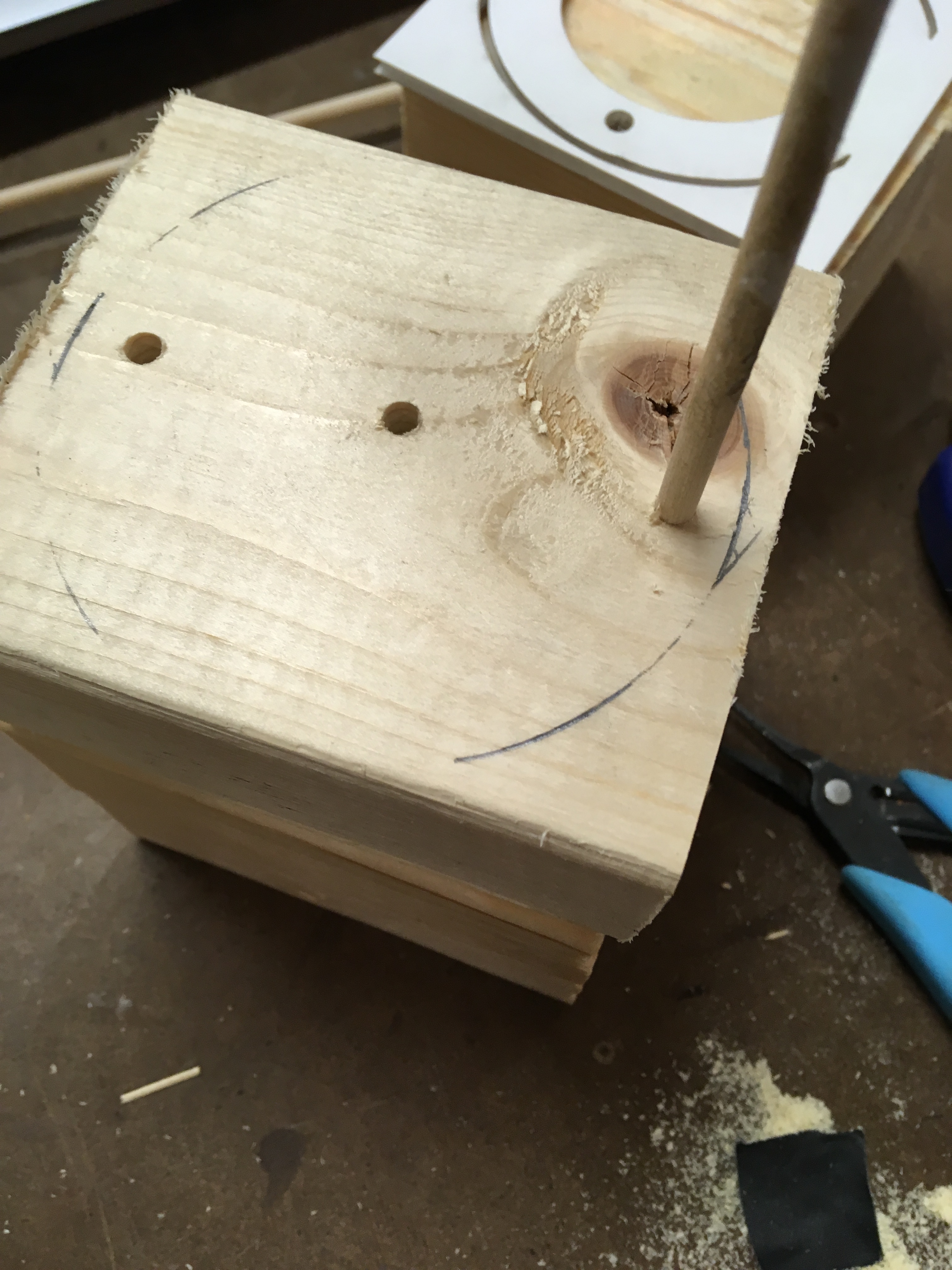

Prepping the top block and larger bottom block. We clamp them together and drill press them together to be double sure that the dowel will fit/align through both blocks.

Prepping the top block and larger bottom block. We clamp them together and drill press them together to be double sure that the dowel will fit/align through both blocks.

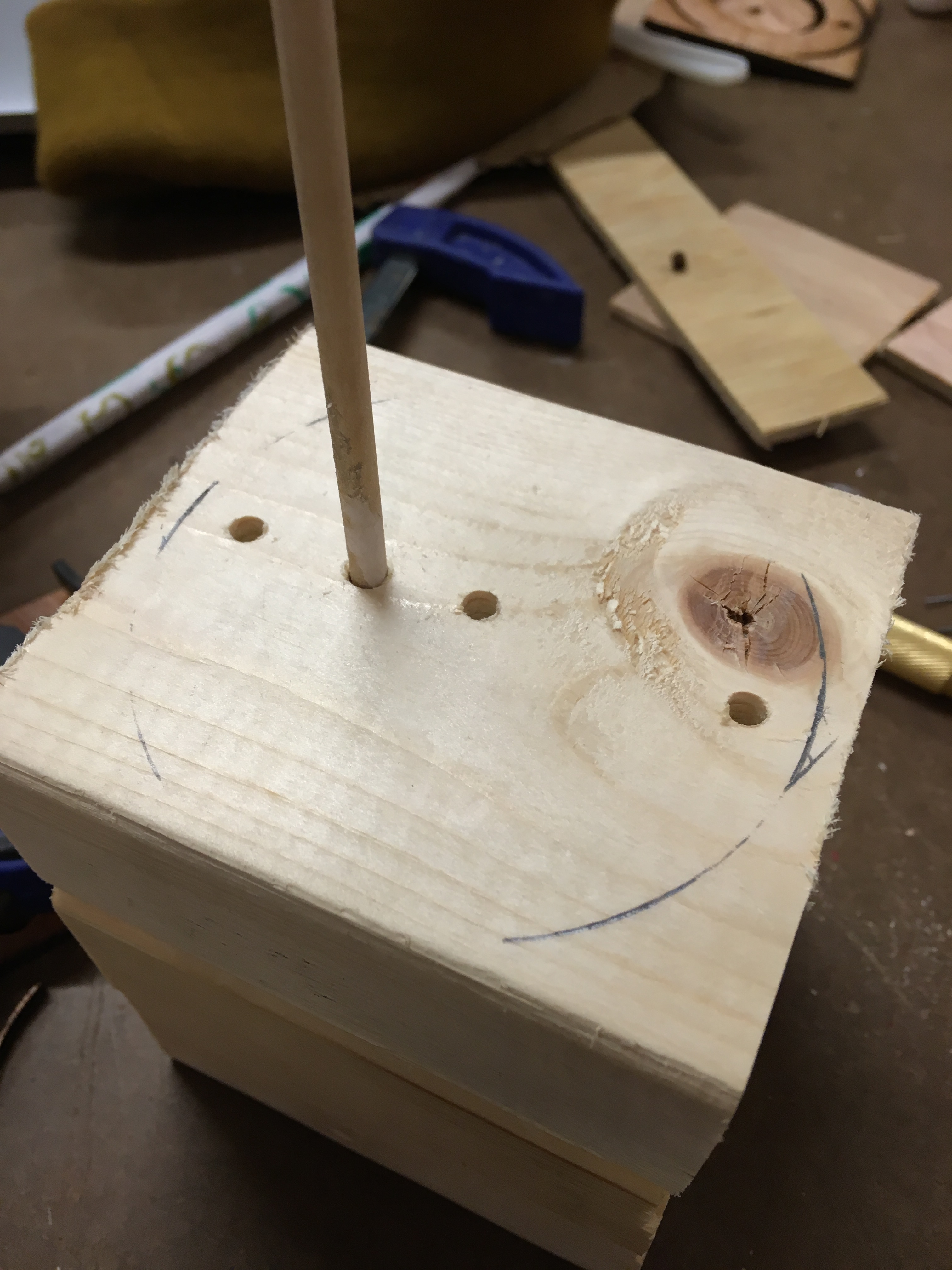

A whole lot of clamps. XY-axis adjusting clamp was a real timesaver in making the three holes in series here.

A whole lot of clamps. XY-axis adjusting clamp was a real timesaver in making the three holes in series here.

Actually drill-press.

Actually drill-press.

Dowel test fail. It fits but too snug.

Dowel test fail. It fits but too snug.

Pancake test: Much better dowel movement with next-size-up drill bit.

Pancake test: Much better dowel movement with next-size-up drill bit.

A jig that fits more snugly on the dowel to trace an accurate circle.

A jig that fits more snugly on the dowel to trace an accurate circle.

Circle traced. And then roughly cut to remove away as much material as possible.

Circle traced. And then roughly cut to remove away as much material as possible.

Using circle-sander and a wheel jig to turn our rough cut circles into beautiful, round wheels.

Using circle-sander and a wheel jig to turn our rough cut circles into beautiful, round wheels.

A beautiful, round wheel.

A beautiful, round wheel.

Dowel test before we start to really repeat everything.

Dowel test before we start to really repeat everything.

Rinse and Repeat!

Everything looks good. Rush to get everything done before the shop closes or someone else needs to move my setup to use the machine…

Clamp; Center-punch; Drill

Clamp; Center-punch; Drill

Dowel test. Whew, it’s looking OK!

Dowel test. Whew, it’s looking OK!

Rough-cut circles, yearning to be smooth wheels.

Rough-cut circles, yearning to be smooth wheels.

And we’re done! Not quite ready for shaping ice blocks, but great for alt framing. Credit to Roland for the Cuneiform Tile.

And we’re done! Not quite ready for shaping ice blocks, but great for alt framing. Credit to Roland for the Cuneiform Tile.

Comments

Benjamin Light

Nice work, love that you made round objects on the sander. I want to see more of your jig and maybe a short video of it being used on the sander.

Glad you used clamps and a vice on the drill press, it makes drilling those holes much more accurate.

Does the top part move smoothly on the dowels?