Skill Builder: Othermill CNC

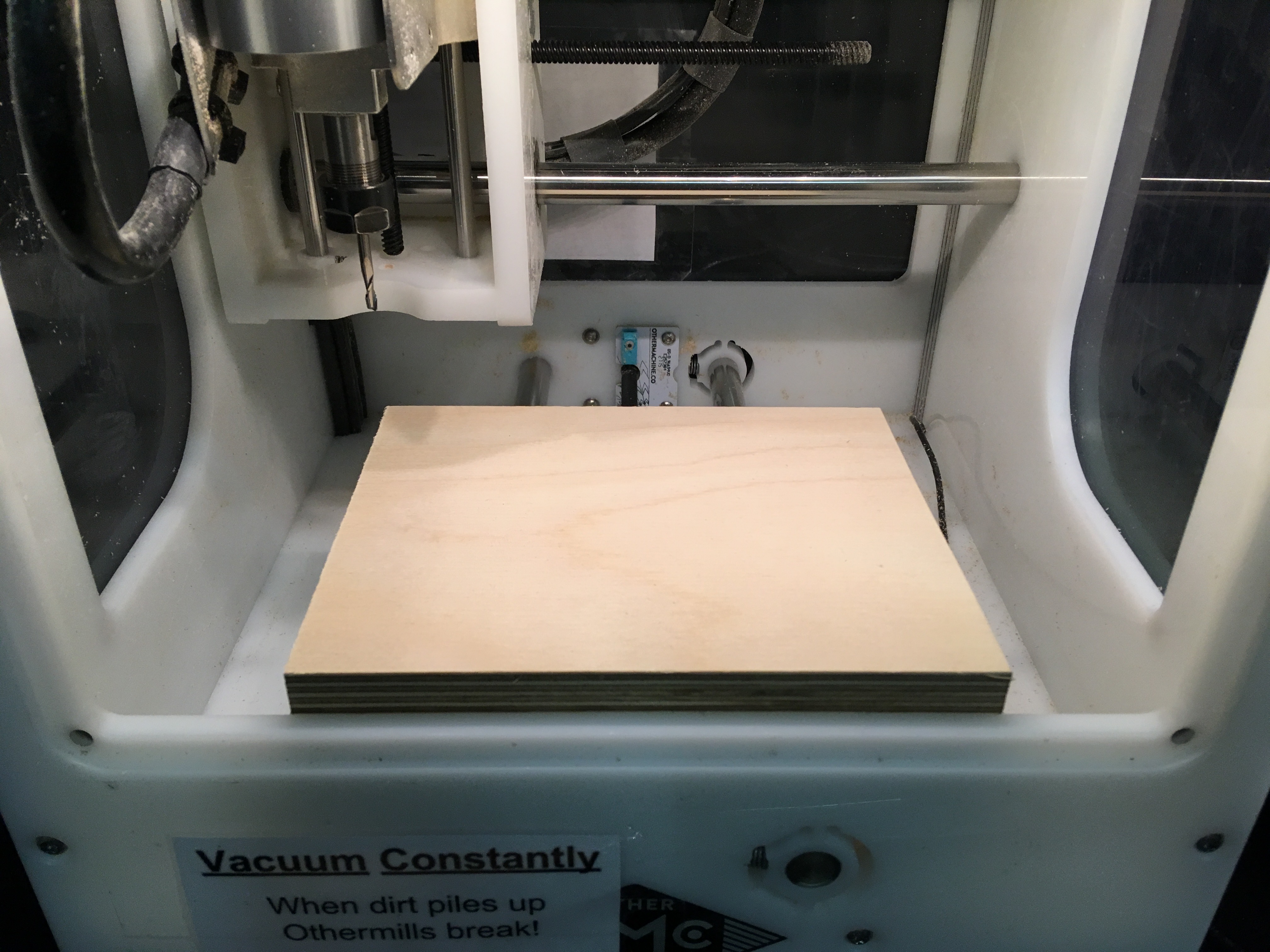

First things first, find some scrap material and make it small. I chose to use plywood from the scrap bin because it’s free and available and thus, forgiving.

Here, I use the bandsaw to rectangular-ize my raw plywood to fit the dimensions of the Othermill CNC bed.

Here, I use the bandsaw to rectangular-ize my raw plywood to fit the dimensions of the Othermill CNC bed.

Nice hipster shot of tools and materials.

Nice hipster shot of tools and materials.

For my design, I borrowed a dinosaur icon from The Noun Project since they have everything and IT’S ALL SVG! With some Illustrator magic, I unify the paths and fix the fills to do what I need. I know the sharp edges of the 8-bit design won’t cut out well, but I want to see what it looks like anyway.

For my design, I borrowed a dinosaur icon from The Noun Project since they have everything and IT’S ALL SVG! With some Illustrator magic, I unify the paths and fix the fills to do what I need. I know the sharp edges of the 8-bit design won’t cut out well, but I want to see what it looks like anyway.

It’s all about the prep

- Click “Change” in BantamTools and it centers the spindle and walks you through the process to change the drill bit.

- Remove the collet, tap to clean, return to spindle.

- Add our 1/8 Flat End Mill Bit and hand tighten.

- Use the handy wrenches to properly tighten.

For material setup, I lined the bed with double-sided tape and placed my raw material on, doing my best to align everything to the bottom left.

For material setup, I lined the bed with double-sided tape and placed my raw material on, doing my best to align everything to the bottom left.

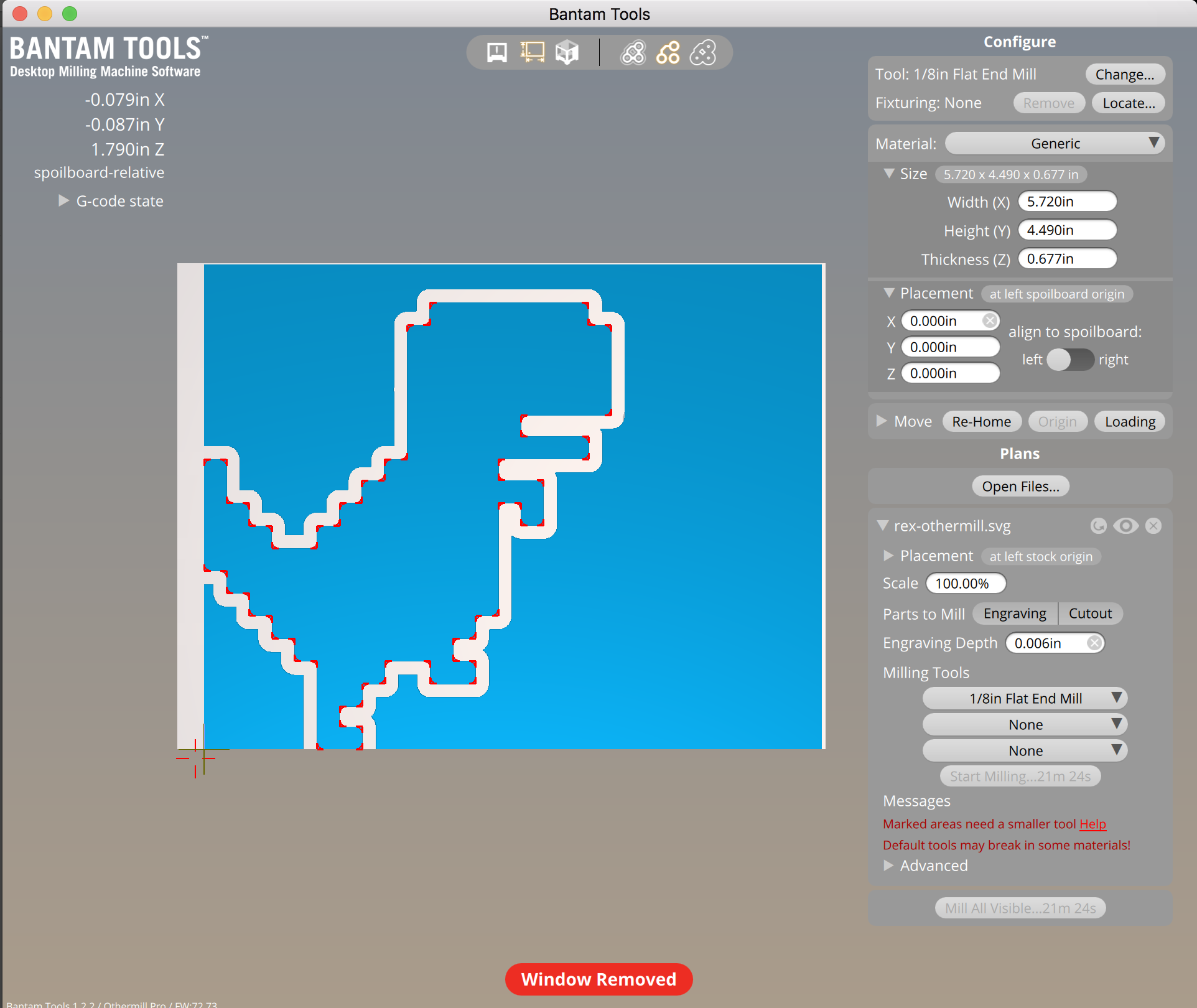

<3 BantamTools shows you the toolpath! And a Mill-er time estimate! <3

<3 BantamTools shows you the toolpath! And a Mill-er time estimate! <3

Ready to Work

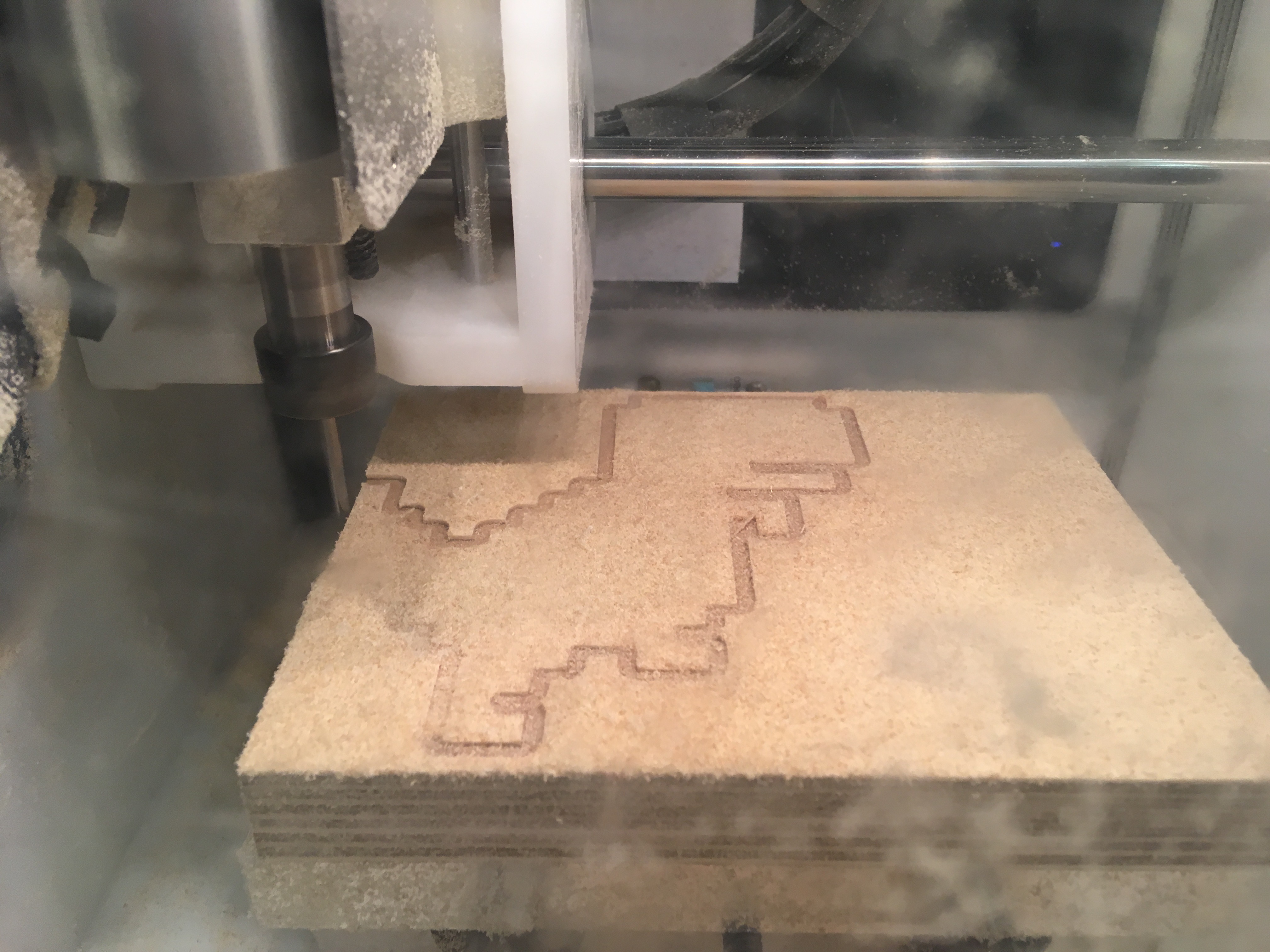

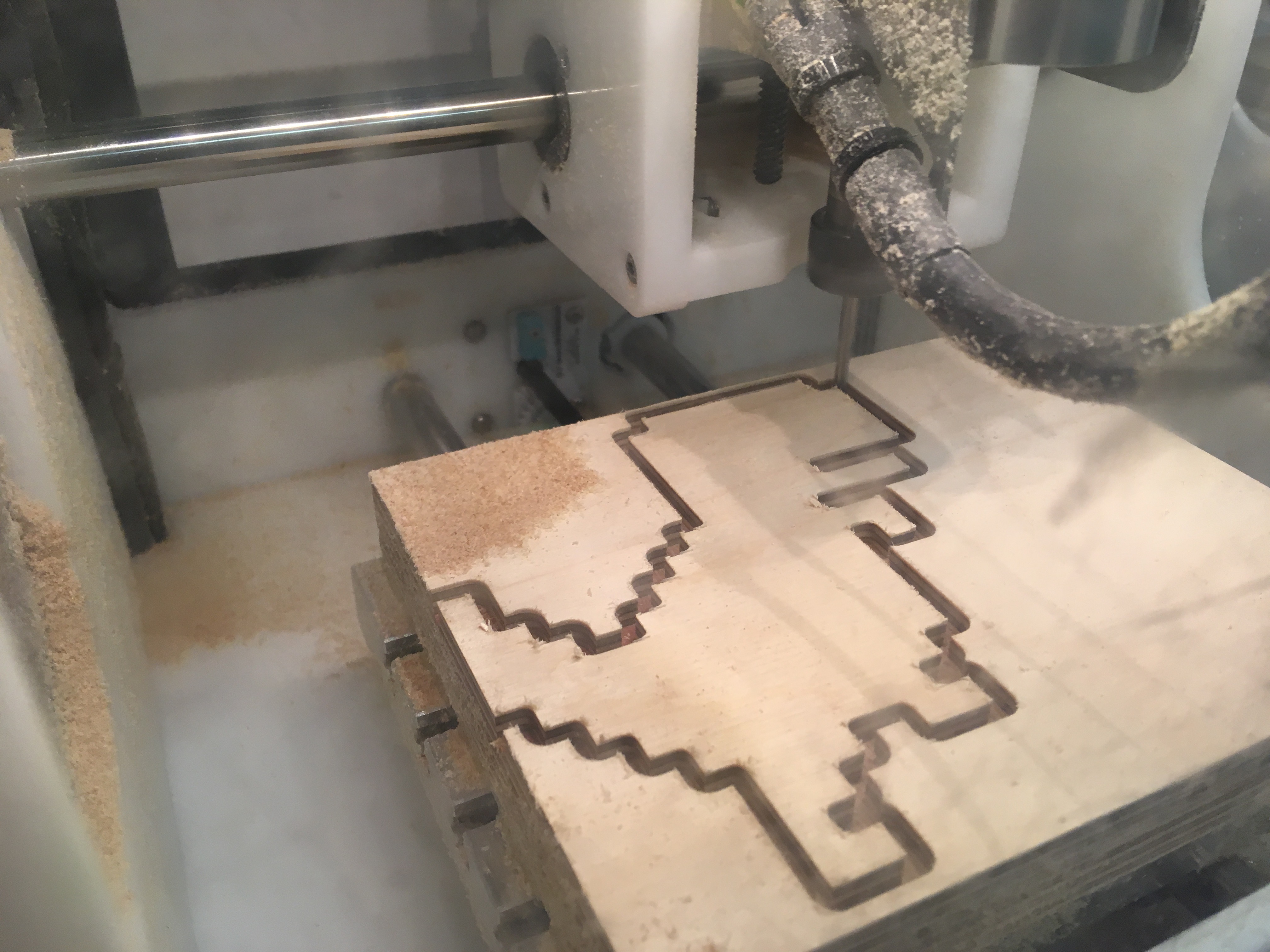

Not seen here, but I actually engraved the top layer gently. Here’s an image of the first cutout (contour?) pass.

Not seen here, but I actually engraved the top layer gently. Here’s an image of the first cutout (contour?) pass.

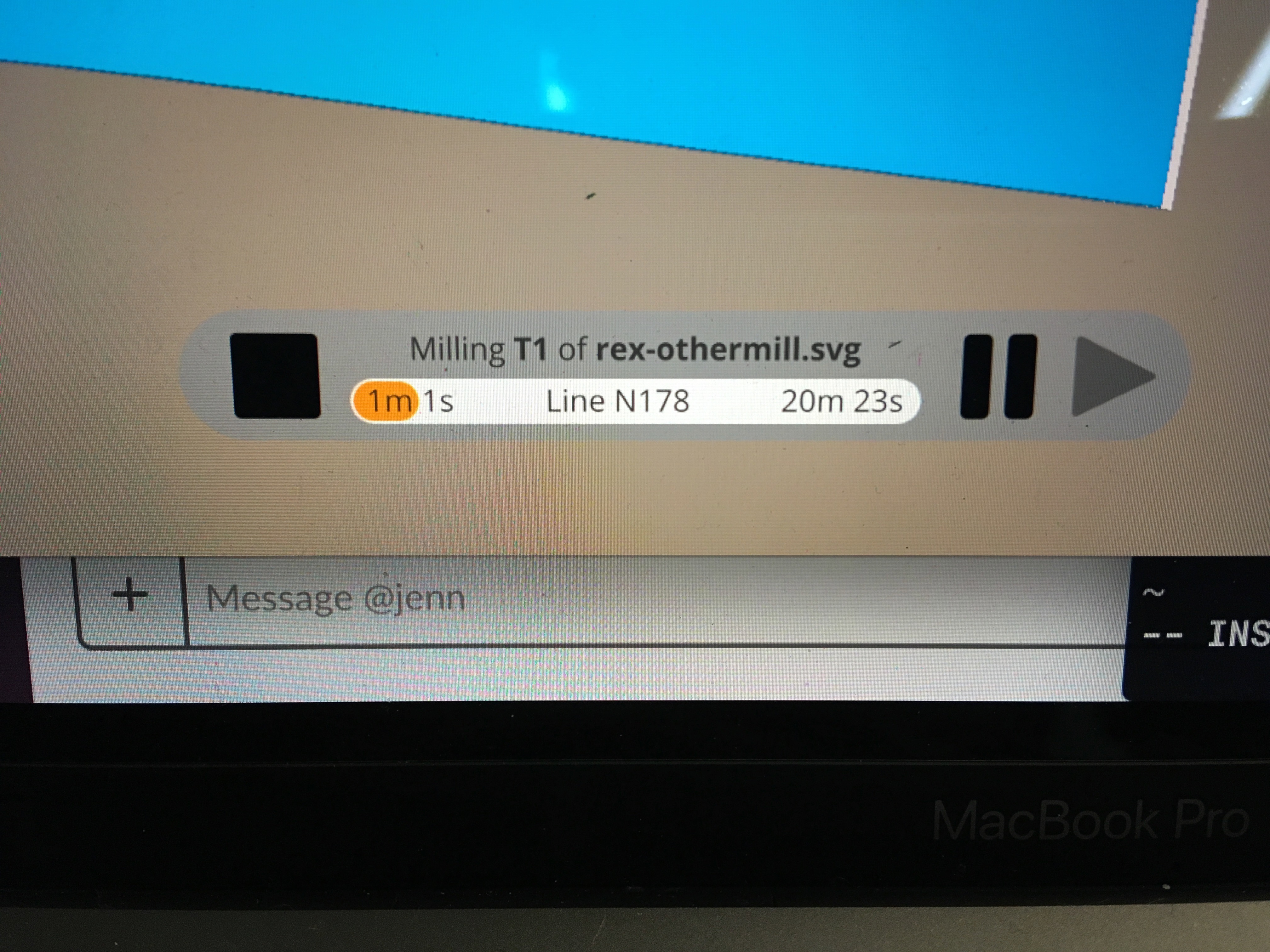

Loving this status bar with an ability to pause. I pause a few times to vacuum.

Loving this status bar with an ability to pause. I pause a few times to vacuum.

The final cutout pass.

The final cutout pass.

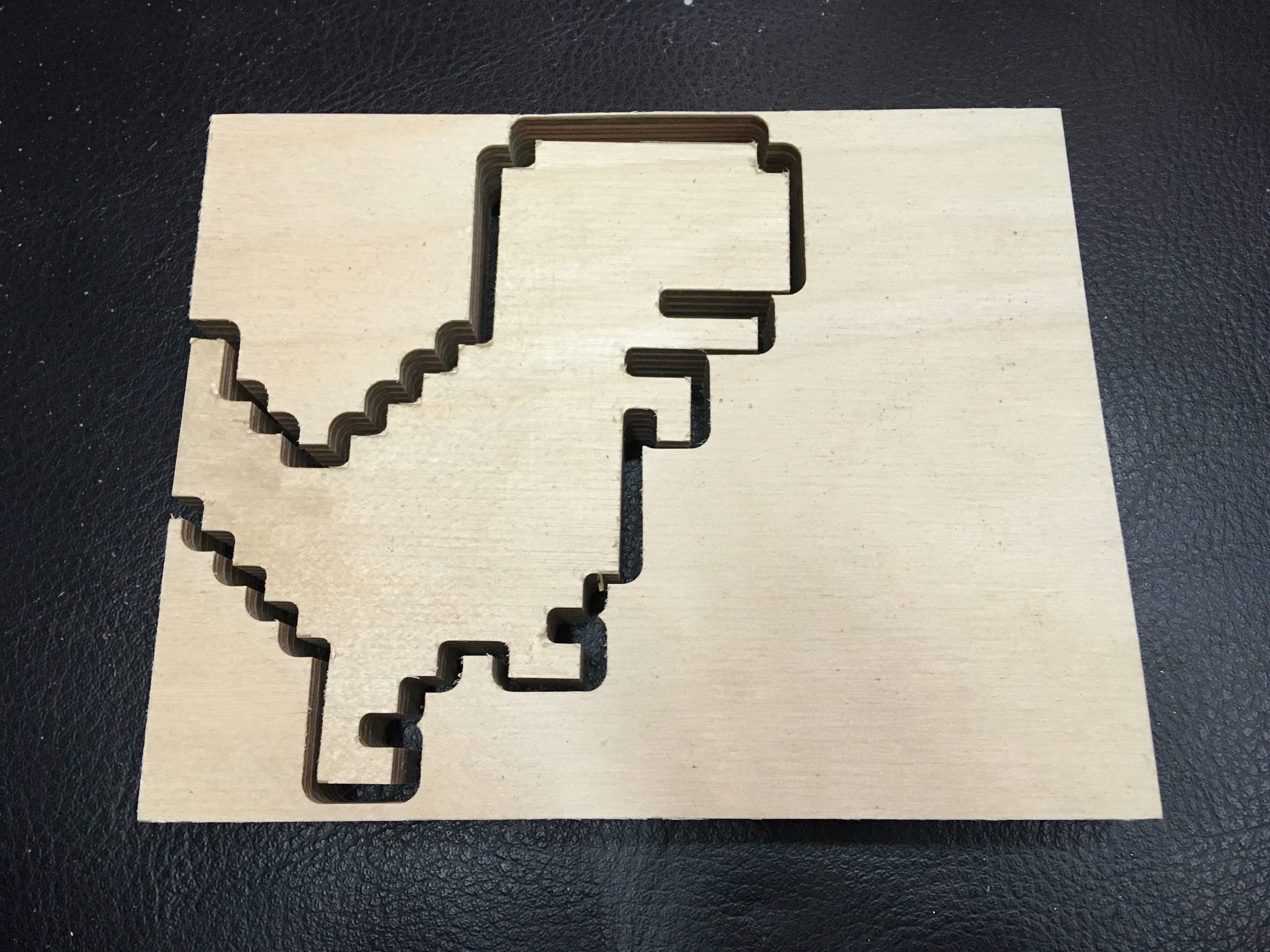

Cutout from above. The sharp edges in the original design turned out better than I expected.

Cutout from above. The sharp edges in the original design turned out better than I expected.

Cute, quick and easy. My cutout dinosaur in about 20 minutes.

Cute, quick and easy. My cutout dinosaur in about 20 minutes.